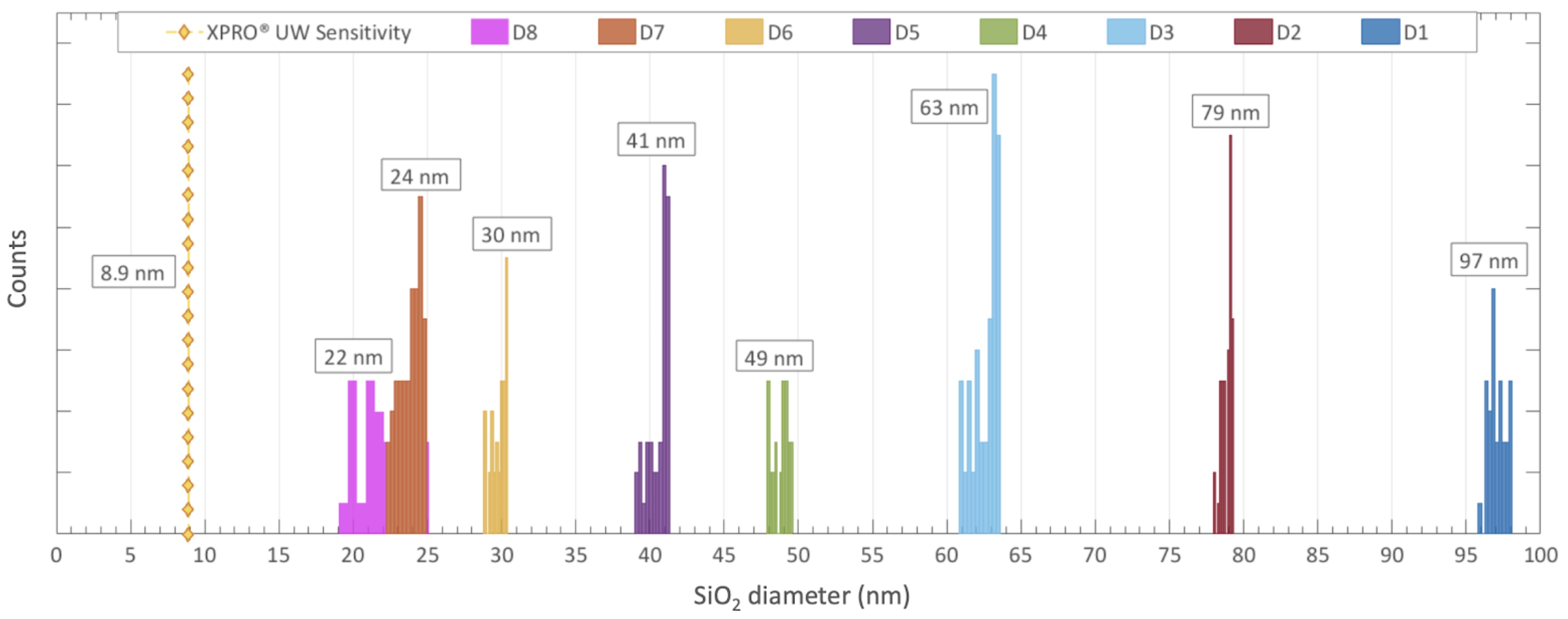

8.9 nm sensitivity breakthrough with visible light.

Unpatterned wafer inspection without DUV baggage.

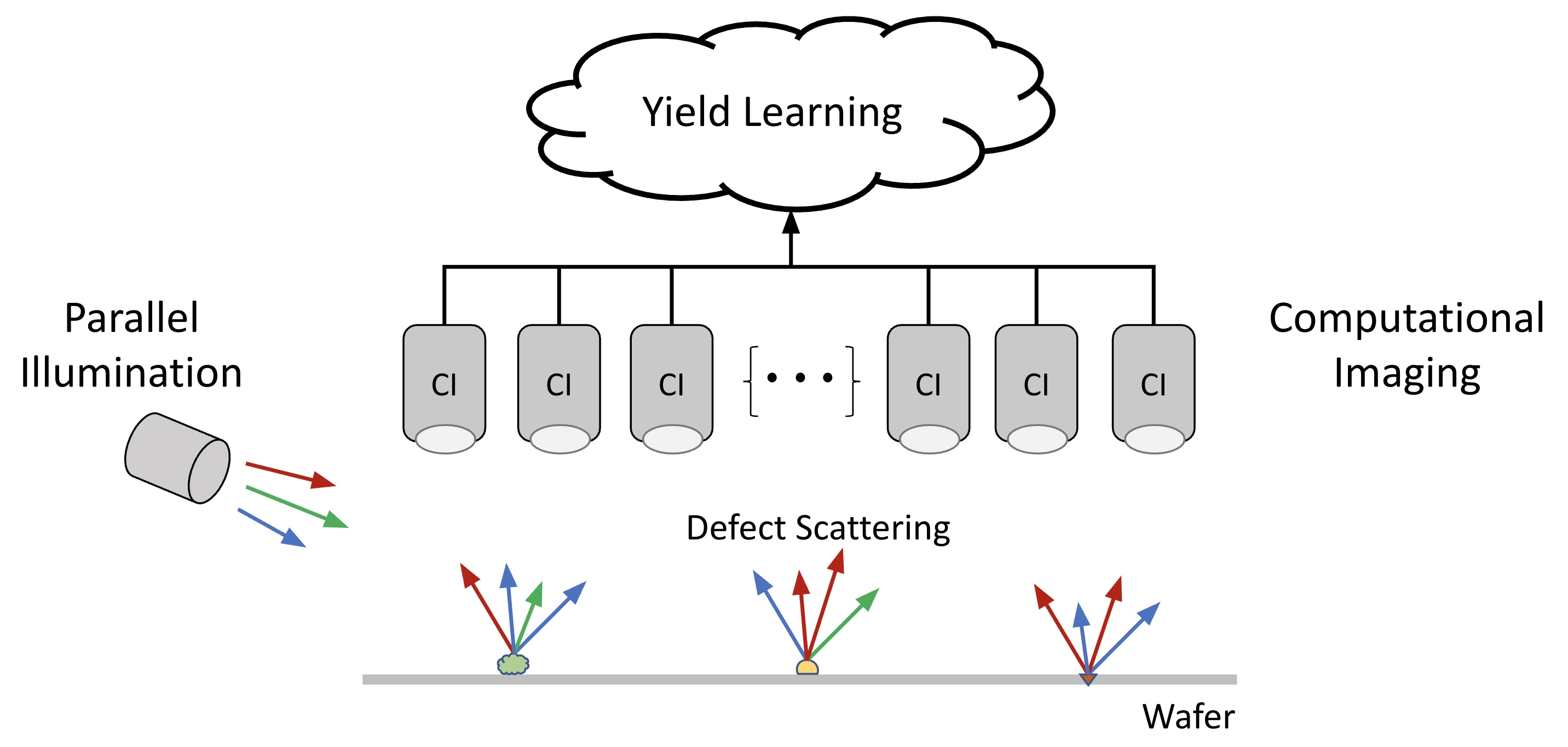

Computational Parallel Inspection® (CPI)

- Wide illumination coverage with visible wavelengths.

- Matched detection with wide field computational imaging.

- Detection, classification & root cause analysis with AI models.

- Backed by 10 patents

Exnodes licenses technology to industry leaders in SEMI.

Accelerate your process at the leading edge.

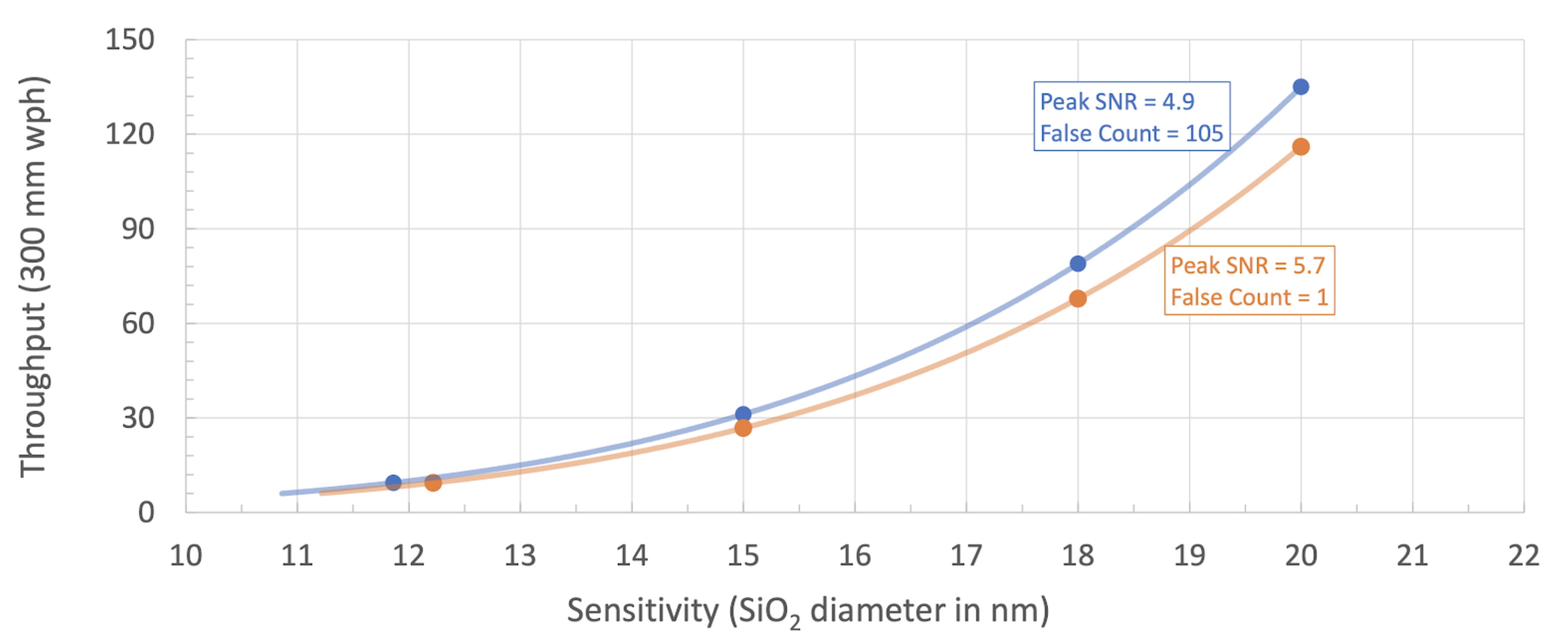

120 wph at 20 nm SiO2 sensitivity.

Real-time feedback loops in 3 nm node volume manufacturing.

Compact footprint enables onboard modules for cluster tools.

Simultaneous detection of 8.9 nm to 100 nm defects.

Validated by industry leaders over a wide range of defect sizes.